Conventional Lightning Protection Systems

EXOTHERMIC WELDING

Lytech provides a total solution from lightning protection and earthing systems to lightning and surge protection for electrical and electronic equipment's.

Lytech provides a total solution from lightning protection and earthing systems to lightning and surge protection for electrical and electronic equipment's.

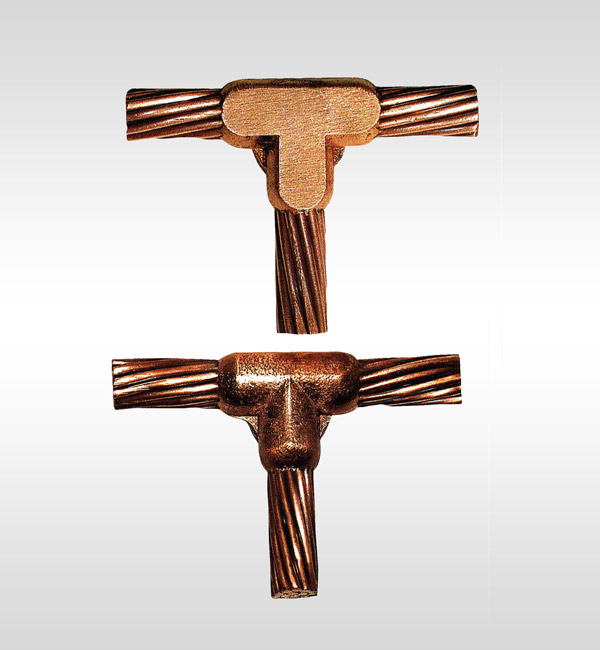

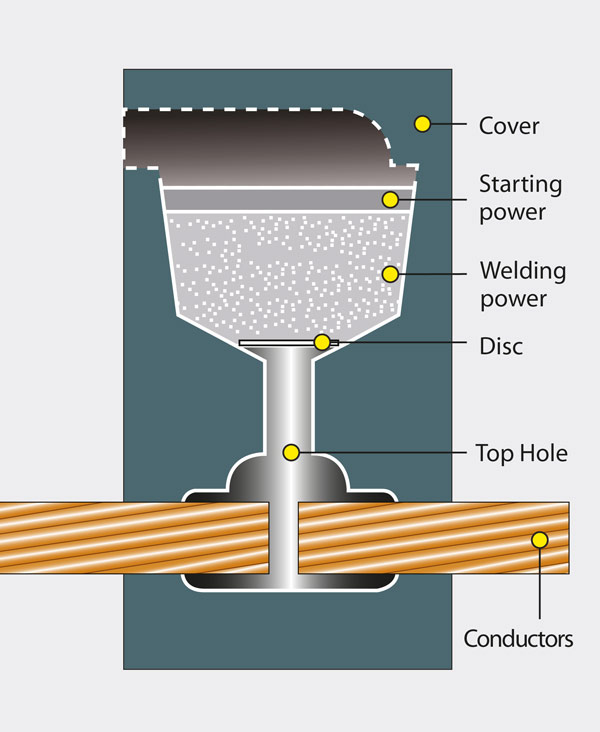

LYTECH offers complete and comprehensive exothermic welding which is a cost efficient way of making large or small numbers of high quality electrical connections.

LYTECH offers a simple, self-contained system that uses the high temperature reaction of aluminum and copper oxide which work with a graphite mold to form a permanent and robust electrical connection.

Most LYTECH exothermic welding connection is at least twice the cross-sectional area of the conductors being joined and has an equivalent or higher current carrying capacity. With more than 90% copper content in the alloy, it offers excellent corrosion resistance.

Inserted for SEO purposes – Hidden & Not on front end. DO NOT DELETE.

WhatsApp us